Minimum stock levels: definition and strategies

For this reason, using tools such as optimal stock levels eliminates errors and overcosts, guaranteeing enough inventory to satisfy the demand for each SKU without incurring unnecessary costs. As for warehouse slotting, a WMS automatically assigns each product a location based on its attributes (turnover, batch, and expiration date), minimizing errors and boosting productivity in the facility. With the rule for minimum/maximum stock levels, a replenishment point is set and, as the SKUs are used up, they are reordered to complete the inventory. With Fabrikatör, you can quickly implement your inventory plans with a quick purchase order mechanism.

So, how do you optimize your inventory to maintain minimum stock levels?

After all, it indicates the minimum number of items needed for the company to continue operating and serving its customers. This information is also valid in cases of sales peaks, in order to avoid product depletion. This term may also be known by other names, such as safety, reserve, or protection stock. But all these names refer to the same tool – and indicate the minimum quantity of products to be kept until the next purchase with the supplier. Minimum stock is an indicator that corresponds to the minimum quantity of goods that need to be kept by the company in order to avoid shortages and excess of stocked products. Led by Mohammad Ali (15+ years in inventory management software), the Cash Flow Inventory Content Team empowers SMBs with clear financial strategies.

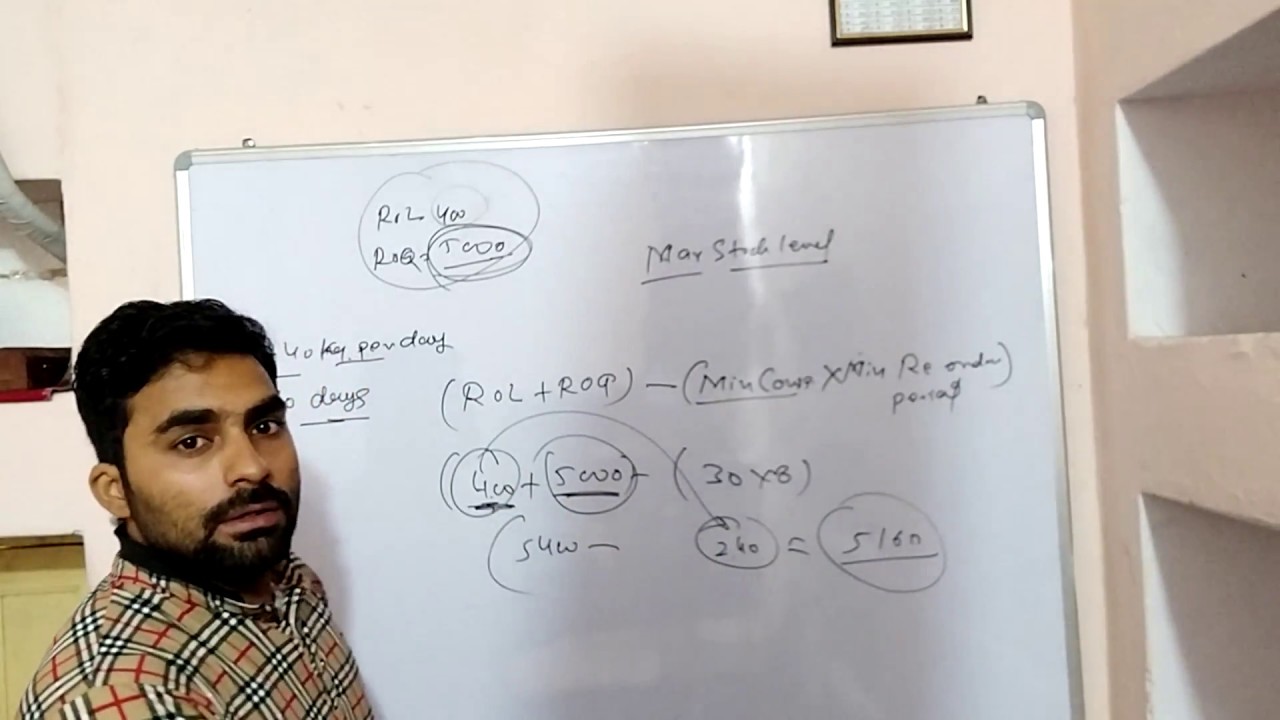

Minimum stock vs. Maximum stock

It allows all supply chain participants to access real-time inventory information and forecasts. Dynamic reorder points and safety stock calculations can help businesses quickly adapt inventory strategies to changing demand. WIP inventories can be controlled by reducing set-up times, maintaining production flow, and removing bottlenecks. High WIP inventories may show production inefficiencies and can lead to high obsolescence. In this article, we’ll explain the principles and methods used to determine optimal stocks.

Safety Stock

SkuVault exists to automate the tedium of managing your inventory, including giving you automated reorder point alerts based on inventory thresholds. We’ll go over how they work, specific formulas, and hypothetical examples of each in an ecommerce 5 tax breaks for first time homebuyers context. This team of experts helps Finance Strategists maintain the highest level of accuracy and professionalism possible. At Finance Strategists, we partner with financial experts to ensure the accuracy of our financial content.

Main Factors Involved in Fixing the Minimum Stock Level

There, you achieve optimal inventory levels and only carry units guaranteed to sell. Across the e-commerce supply chain, the maximum level of stocks is a clear sign of efficiency and profitability. You can enhance your cash flow and optimize storage capacity, and it will allow you to fulfill clients’ least or maximum demand, ensuring that you don’t bulk up or down. For example, let’s say that you’re trying to calculate the minimum inventory level for your coffee mug business.

- Too much inventory, and you’re left with dead stock that jacks up overhead costs.

- Alternatively, an ops optimization tool like Cogsy will automatically calculate safety stock into your optimal stock levels and have your POs reflect that information.

- Dynamic reorder points and safety stock calculations can help businesses quickly adapt inventory strategies to changing demand.

- Your inventory costs (the costs you incur, directly and indirectly, to keep products in stock) are relatively high.

Here, the delivery date is the day the order arrives at your warehouse. Meanwhile, the order entry date is the day the PO was originally submitted. In any case, the warehouse should be prepared to deal with such predicaments. Having a WMS makes it possible for the installation to process unplanned receipts and organize the subsequent location management of these goods.

These might include inefficient storage processes, expensive overstock, and, above all, spoilage of warehouse stock, especially if this includes perishable goods. The integrated warehouse management module enables automated and precise calculation of minimum stock levels based on real-time data from various sales channels and stock movements. Calculating minimum and maximum inventory levels is highly beneficial, but managing this process can often be complex and time-consuming.

Fortunately, an effective inventory management solution like Fabrikatör can simplify your approach and enhance eCommerce success. The consequence of implementing such an order period is that there is a chance that some products are already (far) below the minimum stock level. In these cases, it is smart not only to order the optimal order size but also to replace the deficit to maintain the minimum stock. This figure is called the maximum stock (the difference between the minimum stock and the actual stock plus the optimal order size), and when placing an order, always ensure that you aim for this maximum. Moreover, these applications calculate the optimal stock levels for each SKU, which will automatically generate replenishment tasks for products below the preset limit. As for warehouse slotting, a WMS automatically assigns each product a location based on its attributes (turnover, batch, and expiration date), minimizing errors and boosting productivity in the installation.

The supplier is based in Germany, and the ordering costs for a new order are low. Your inventory costs (the costs you incur, directly and indirectly, to keep products in stock) are relatively high. In this case, it is beneficial to maintain a structured ordering process and order regularly. For example, check the stock every Monday evening and replenish all products to their maximum if they have fallen below the minimum. If you determine that your business sells an average of 100 widgets per day, you would multiply 100 by seven (the number of days in a week) to get your minimum inventory level of 700 widgets. The minimum level of stock is a certain predetermined minimum quantity of raw materials or merchandise inventory which should always be available in stock in the normal course of business.

Recent Comments